Product Description

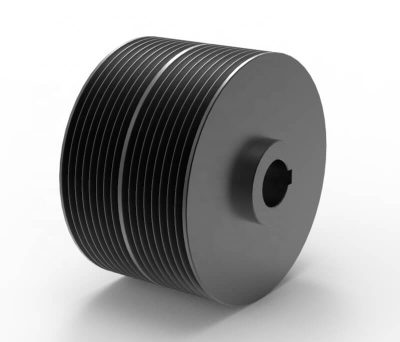

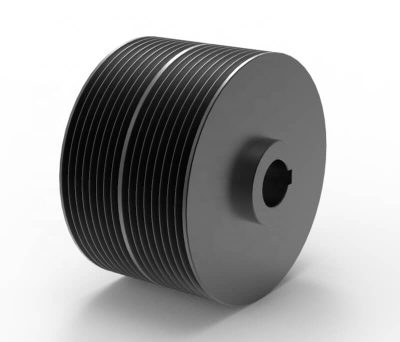

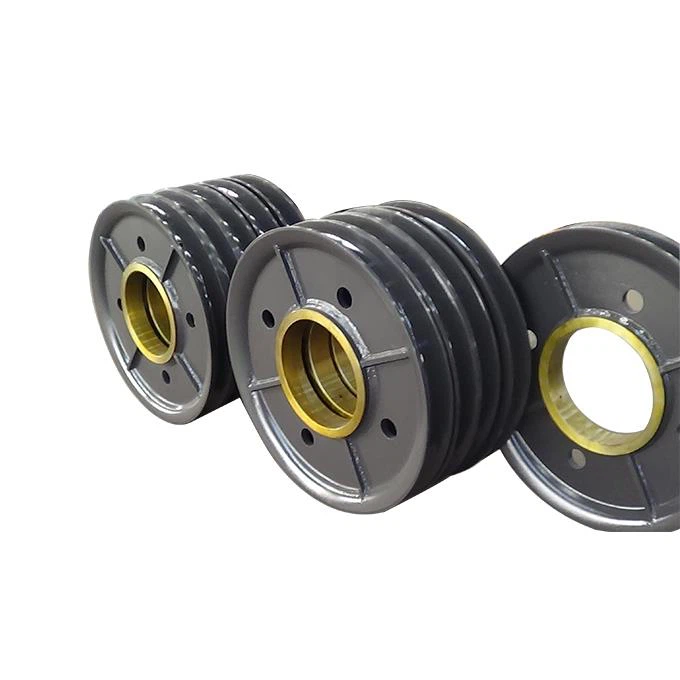

Fast Sell Multiple Engine/Size Standard Crankshaft Tensioner, Crankshaft Pulley Old Type Two Grooves Fit for 6D31 Engine Many Types of Machine Excavator.

Our main products:

steel cover lock, filter, oil grid, pump, cylinder head, crankshaft, camshaft, connecting rod, connecting rod bearing, valve, plunger, nozzle, exhaust valve, engine assembly, intake pump , fan blade, engine preheater, radiator, intake valve, main bearing, crankshaft bearing, nozzle, nozzle pipe, oil pump, piston, piston pin, piston ring, plunger, valve seat, thrust bearing, valve guide, valve Seats, valve seals, gasket sets, water pumps, turbochargers, generators, starters, sensors…

Please click here>>>>Contact us for more factory price,shipping and discounts

| ENGINE CUSHION | ||||||||||||||

| NO. | LB NO. | Model | OEM NO. | Name | NO. | LB NO. | Model | OEM NO. | Name | NO. | LB NO. | Model | OEM NO. | Name |

| 1 | KLB-Q3 | BELT TENSIONER | 15 | KLB-Q0017 | SK350-8 4pieces groove | BELT TENSIONER | 28 | KLB-Q0032 | 4BD1 4BG1 A:singlePK B:3PK |

3389198 | CRANKSHAFT PULLEY | |||

| 3 | KLB-Q0003 | 6CT | 3967190 | BELT TENSIONER | 16 | KLB-Q0018 | SK460 3pieces groove | BELT TENSIONER | 29 | KLB-Q0033 | EX200-1/3 6BD1 | CRANKSHAFT PULLEY | ||

| 4 | KLB-Q0004 | EC210 | 462280 | BELT TENSIONER | 17 | KLB-Q0019 | VOLVO360 | BELT TENSIONER | 30 | KLB-Q0034 | 6D31(NEW) | 173*140*34 | CRANKSHAFT PULLEY | |

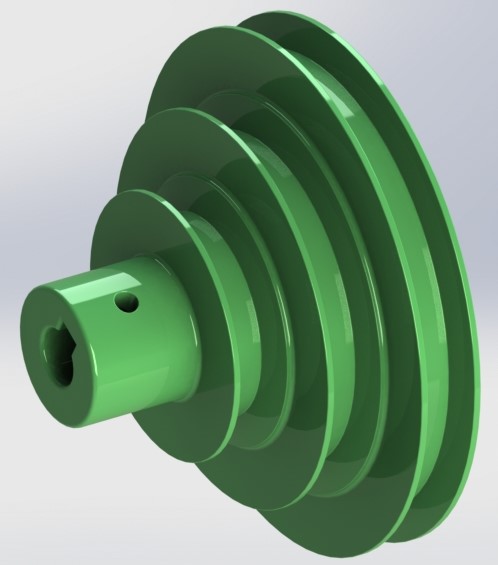

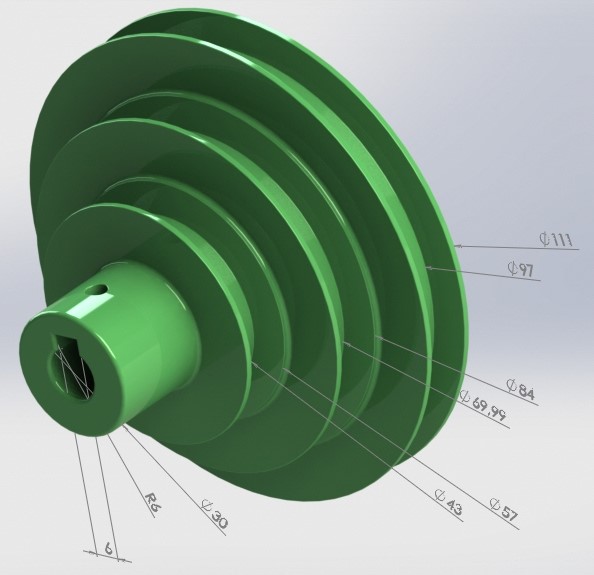

| 5 | KLB-Q0005 | E325C | 144-1102 | BELT TENSIONER | 18 | KLB-Q571 | S6K | BELT TENSIONER | 31 | KLB-Q0035 | 6D31(OLD) | 160*120*34 | CRANKSHAFT PULLEY | |

| 6 | KLB-Q0006 | PC200-8 | BELT TENSIONER | 19 | KLB-Q0571 | PC60 4D95 | 150*66*43 | CRANKSHAFT PULLEY | 32 | KLB-Q0036 | E200B/320 | 160*113*45 | CRANKSHAFT PULLEY | |

| 7 | KLB-Q0007 | VOLVO210 stainless steel | BELT TENSIONER | 20 | KLB-Q0571 | PC120-6 | CRANKSHAFT PULLEY | 33 | KLB-Q0037 | E320B | 160*110*45 | CRANKSHAFT PULLEY | ||

| 8 | KLB-Q0008 | VOLVO360 | BELT TENSIONER | 21 | KLB-Q571 | PC200-3 6D105 | 144*113*39 6138-31-1480 | CRANKSHAFT PULLEY | 34 | KLB-Q0038 | E320C | 170*143*45 | CRANKSHAFT PULLEY | |

| 9 | KLB-Q0009 | CA016/C7 | BELT TENSIONER | 22 | KLB-Q0571 | PC200-5 6D95 | 150*110*41 6207-31-1410 | CRANKSHAFT PULLEY | 35 | KLB-Q0039 | DH220-5 DB58 | CRANKSHAFT PULLEY | ||

| 10 | KLB-Q571 | VOLVO480 with Belt groove | BELT TENSIONER | 23 | KLB-Q0571 | PC200-6 6D95 | 155*154*42 6209-31-1410 | CRANKSHAFT PULLEY | 36 | KLB-Q0014 | DH | 2107-6004B | BELT TENSIONER | |

| 11 | KLB-Q0011 | VOLVO480 | BELT TENSIONER | 24 | KLB-Q0026 | PC200-6 6D102 | 6735-61-3280 220*54*19 | CRANKSHAFT PULLEY | 37 | KLB-Q0015 | EX | BELT TENSIONER | ||

| 12 | KLB-Q0012 | VOLVO480 | BELT TENSIONER | 25 | KLB-Q0571 | PC300-3 PC400 6D125 | 182*118*43 | CRANKSHAFT PULLEY | 38 | KLB-Q571 | EX200-5 6BG1 3pieces groove | 230*120*40 | CRANKSHAFT PULLEY | |

| 13 | KLB-Q0013 | E320C | BELT TENSIONER | 26 | KLB-Q571 | A:PC300-6 6D108 doublePK | 144*127*40 | CRANKSHAFT PULLEY | 39 | KLB-Q0030 | 4D31 | 168*100*35 | CRANKSHAFT PULLEY | |

1Q:What is your brand?

1A:Our own brand: Mita Group and its range of excavator parts.

2Q:Do you have your own factory? Can we have a visit?

2A:Absolutely, you are alwayswelcome to visit our factory.

3Q:How do you control the quality of the products?

3A:Our factory was obtained the ISO9001CERTIFICATE.Every process of the production is strictly controlled. And all products will be inspected by QC before shipment.

4Q:How long is the delivery time?

4A:2 to 7 days for ex-stock orders. 15 to 30 days for production.

5Q:Can we print our company logo onproduct and package?

5A:Yes, but the quantity of the order is required. And we need you to offer the Trademark Authorization to us.

6Q:Can you provide OEM BRAND package?

6A:Sorry, we can only offer our company ACT BRAND package or neutral packing,blank package ifyou need, and the Buyers’ Brand as authorized.7Q:How long is the warranty period?7A:3 months /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Material: | Aluminum |

| Type: | Crankshaft Tensioner |

| Transport Package: | Standard Packaging |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do wall mount pulley systems contribute to improved efficiency and functionality in various settings?

Wall mount pulley systems offer several advantages that contribute to improved efficiency and functionality across various settings. Here’s a detailed explanation:

1. Mechanical Advantage:

Wall mount pulleys provide a mechanical advantage by distributing the force applied to the system. By redirecting the force through multiple pulleys, they reduce the amount of effort required to lift or move heavy objects. This increased mechanical advantage improves efficiency and allows for easier and more efficient operation.

2. Load Distribution:

Pulley systems distribute the load evenly across multiple pulleys and ropes or cables. This load distribution minimizes stress and strain on individual components, enhancing the system’s overall functionality and longevity. It also allows for the lifting or movement of heavier loads, expanding the capabilities of the system.

3. Versatility:

Wall mount pulley systems are highly versatile and can be adapted to various applications. They can be configured with different types and sizes of pulleys, ropes, or cables to meet specific needs. This versatility makes them suitable for a wide range of settings, including construction sites, manufacturing facilities, recreational areas, and residential spaces.

4. Space Optimization:

Wall mount pulleys utilize vertical space efficiently, making them ideal for environments with limited floor space. By mounting the pulleys on walls or overhead structures, they eliminate the need for bulky equipment or floor-mounted systems. This space-saving design allows for better organization and utilization of the available area.

5. Precise Positioning:

Wall mount pulleys enable precise positioning of objects or loads. By adjusting the position of the ropes or cables on the pulleys, users can control the vertical or horizontal movement with accuracy. This precision is particularly valuable in applications such as theatrical rigging, construction hoisting, or mechanical systems that require precise load manipulation.

6. Scalability:

Pulley systems are scalable, meaning they can be expanded or modified to accommodate changing needs. Additional pulleys, ropes, or cables can be added to the system to increase load capacity or change the mechanical advantage. This scalability provides flexibility and adaptability, allowing the system to grow or be adjusted as required in different settings.

7. Safety:

Wall mount pulley systems can enhance safety in various settings. By distributing the load and reducing the effort required for lifting or moving heavy objects, they minimize the risk of strain or injury to individuals operating the system. Additionally, the controlled movement provided by pulley systems allows for safer and more precise positioning of loads, reducing the risk of accidents or damage to the surroundings.

Overall, wall mount pulley systems improve efficiency and functionality in various settings by providing mechanical advantage, load distribution, versatility, space optimization, precise positioning, scalability, and enhanced safety. Their ability to optimize force distribution and enable controlled movement makes them valuable tools across industries and applications.

How do wall mount pulleys contribute to space-saving and organization?

Wall mount pulleys are highly effective in contributing to space-saving and organization in various settings. Here’s a detailed explanation of how they achieve these benefits:

1. Vertical Storage:

By utilizing wall mount pulleys, items can be stored vertically, suspended from the ceiling or mounted on walls. This vertical storage approach maximizes the available space, especially in areas with limited floor space. It allows for efficient utilization of overhead and wall space, keeping the floor area clear and uncluttered.

2. Clearing Floor Space:

Wall mount pulleys help free up valuable floor space by lifting and suspending items off the ground. This is particularly useful in garages, workshops, or utility rooms where bulky items like bicycles, kayaks, or ladders can be stored overhead using pulley systems. Clearing the floor space improves mobility, reduces tripping hazards, and creates a cleaner and more organized environment.

3. Easy Access and Retrieval:

Using wall mount pulleys, items can be easily accessed and retrieved when needed. The pulley systems allow for smooth lifting, lowering, and retraction, making it convenient to reach stored items. This ease of access promotes efficient organization and saves time in locating and retrieving tools, equipment, or other stored objects.

4. Customizable Storage Solutions:

Wall mount pulleys offer flexibility in designing and customizing storage solutions. The height at which items are suspended can be adjusted by simply raising or lowering the pulleys. This adaptability allows for accommodating items of various sizes and shapes, optimizing the use of available space, and tailoring the storage system to specific needs.

5. Enhanced Organization:

By utilizing wall mount pulleys, items can be organized and categorized more effectively. Grouping similar items together and assigning specific pulleys or designated areas for different categories helps create a systematic and organized storage system. This not only enhances the overall appearance but also facilitates easy identification and retrieval of stored items.

6. Multi-Purpose Functionality:

Wall mount pulleys can serve multiple purposes, further contributing to space-saving and organization. A single pulley system can be used for storing different items by simply changing the attachments or hooks. This versatility allows for efficient use of the pulley systems and maximizes their organizational benefits.

Overall, wall mount pulleys provide practical solutions for space-saving and organization. They optimize storage capacity, create a clutter-free environment, and offer convenience in accessing and retrieving stored items. By incorporating wall mount pulleys into storage systems, both residential and commercial spaces can benefit from improved functionality and enhanced organization.

In which scenarios and industries are multiple pulley systems commonly employed?

Multiple pulley systems, also known as block and tackle systems, are commonly employed in various scenarios and industries where heavy lifting or load manipulation is required. Here are some scenarios and industries where multiple pulley systems are commonly used:

1. Construction:

Multiple pulley systems are extensively used in the construction industry for lifting heavy materials and equipment. They are employed in tasks such as hoisting construction materials to elevated heights, moving heavy machinery, and facilitating the installation of structural components.

2. Rigging and Sailing:

In the rigging and sailing industry, multiple pulley systems are utilized to control the positioning and tensioning of sails, ropes, and rigging on sailboats and larger vessels. These systems allow sailors to adjust the sail area and control the direction of the sail, enabling efficient propulsion and maneuverability.

3. Entertainment and Theater:

In the entertainment and theater industry, multiple pulley systems are employed for various purposes, such as lifting and moving stage props, scenery, and lighting equipment. These systems enable quick and precise changes in stage setups and facilitate dynamic performances.

4. Industrial Manufacturing:

In industrial manufacturing, multiple pulley systems are used for lifting and moving heavy machinery, components, and materials within factories and production facilities. They provide the necessary mechanical advantage to handle large loads safely and efficiently.

5. Mining and Extraction:

The mining and extraction industry relies on multiple pulley systems for various applications, including lifting and transporting heavy materials, lowering and retrieving mining equipment into underground mines, and facilitating the movement of minerals and ores across processing plants.

6. Material Handling and Logistics:

In material handling and logistics operations, multiple pulley systems are employed for tasks such as loading and unloading cargo, lifting and moving pallets, and operating conveyor systems. These systems enhance efficiency and productivity in warehouses, distribution centers, and shipping facilities.

7. Rescue and Emergency Services:

Multiple pulley systems play a crucial role in rescue and emergency services. They are used for tasks such as high-angle rescues, where individuals or equipment need to be lifted or lowered from elevated locations safely. These systems provide the necessary mechanical advantage to perform such operations with precision and control.

8. Agriculture and Farming:

In agriculture and farming, multiple pulley systems are utilized for various purposes, including lifting and moving heavy farm equipment, tensioning fences and cables, and facilitating the handling of large bales or hay. These systems assist farmers in performing tasks efficiently and reducing manual labor.

These are just a few examples, and multiple pulley systems find applications in various other industries and scenarios where heavy lifting, load manipulation, or precise control is required.

editor by CX

2024-05-14