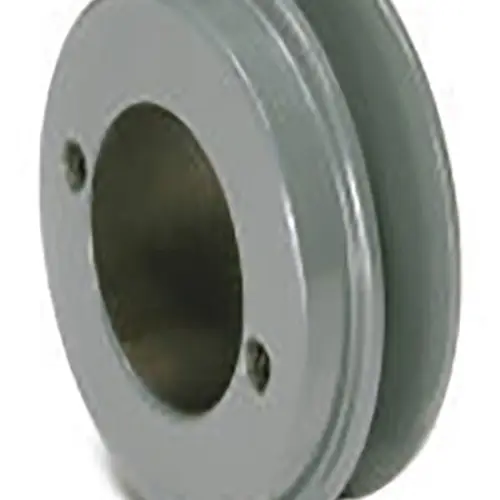

China High Quality Multiple-Groove V-Belt Pulley European Standard Type SPA CHINAMFG Spc Spz Motor V-Belt Pulley Air Compressor Fan Pulley

The China High Quality Multiple-Groove V-Belt Pulley European Standard Type SPA CHINAMFG Spc Spz Motor V-Belt Pulley Air Compressor Fan Pulley is a top-notch product that meets European standards. It is available in various options to suit different needs:

European Standards

a) V-belt pulley for taper bushing: SPZ, SPA, SPB, SPC, up to 10 grooves

b) Adjustable speed V-belt pulleys and variable speed pulleys

c) Flat belt pulleys and conveyor belt pulleys

American Standard

a) Sheaves for taper bushing: 3V, 5V, 8V

b) Sheaves for QD bushings: 3V, 5V, 8V

c) Sheaves for split taper bushing: 3V, 5V, 8V

d) Sheaves for 3L, 4L or A, and 5L or B belts: AK, AKH,2AK, 2AKH, BK, BKH,2BK, 2BKH, 3BK

e) Adjustable sheaves: poly V-pulley, multi-pitch H, L, J, K and M

Our company specializes in supplying a wide range of industrial products. In addition to the China High Quality Multiple-Groove V-Belt Pulley, we also offer agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in providing high-quality products, competitive prices, and exceptional customer service. Customization of drawings and samples is welcomed.

Frequently Asked Questions (FAQs)

1. What are the available options for the V-belt pulleys?

The V-belt pulleys are available in various options, including SPZ, SPA, SPB, SPC types with up to 10 grooves. Additionally, adjustable speed V-belt pulleys, variable speed pulleys, flat belt pulleys, and conveyor belt pulleys are also offered.

2. What are the sheave options for the American standard pulleys?

The American standard pulleys come with sheave options for taper bushings (3V, 5V, 8V), QD bushings (3V, 5V, 8V), split taper bushings (3V, 5V, 8V), and belts like 3L, 4L or A, 5L or B (AK, AKH, 2AK, 2AKH, BK, BKH, 2BK, 2BKH, 3BK). The adjustable sheaves include poly V-pulley and multi-pitch options like H, L, J, K, and M.

3. What is the delivery time and payment terms?

The delivery time for the products may range from 15 to 30 days, depending on the product type and level of customization. As for the payment terms, a 30% T/T payment in advance is required, and the balance is to be paid before shipment.

4. Is it possible to request samples?

Yes, we offer samples free of charge. However, the cost of freight needs to be covered by the customer.

5. What factors determine the MOQ and price of the products?

As an OEM company, the MOQ and price can vary based on factors such as size, material, and specific requirements. Costly or standard products generally have a lower MOQ. To get an accurate quotation, please provide us with all the relevant details.

Performance Characteristics of Multiple Pulley

Multiple pulleys offer several performance characteristics that make them highly desirable in various applications. These characteristics include:

1. Increased Mechanical Advantage: Multiple pulleys provide a mechanical advantage by distributing the load across several grooves, reducing the amount of force required to lift or move heavy objects.

2. Enhanced Efficiency: With the use of multiple grooves, friction is minimized, resulting in improved efficiency and reduced wear and tear on the system.

3. Versatility: Multiple pulleys can be configured in various ways to achieve different mechanical advantages and adapt to different load capacities.

4. Smooth Operation: The design of multiple pulleys ensures smooth operation, allowing for precise and controlled movement of loads.

Types and Characteristics of Multiple Pulley

Multiple pulleys come in different types, each with its own unique characteristics. Some common types include:

1. Fixed Multiple Pulley: This type of pulley is stationary and provides a fixed mechanical advantage. It is often used in applications where the load needs to be lifted or moved in a vertical direction.

2. Movable Multiple Pulley: A movable multiple pulley can be adjusted to achieve different mechanical advantages. It offers flexibility in load handling and is commonly used in rigging systems.

3. Combination Pulley: A combination pulley combines both fixed and movable pulleys, providing increased mechanical advantage and versatility in load handling.

Advantages of Multiple Pulley Materials

Multiple pulleys can be made from a variety of materials, each offering its own advantages. Some common materials used in multiple pulley manufacturing include:

1. Steel: Steel multiple pulleys are known for their strength and durability. They can withstand heavy loads and provide excellent resistance to wear and corrosion.

2. Nylon: Nylon multiple pulleys are lightweight and have low friction properties. They are ideal for applications where reduced noise and vibration are important.

3. Aluminum: Aluminum multiple pulleys are lightweight yet strong. They offer good resistance to corrosion and are often used in applications where weight is a concern.

Application of Multiple Pulley

Multiple pulleys find extensive use in various fields, including:

1. Industrial Machinery: Multiple pulleys are commonly used in industrial machinery for material handling, conveyor systems, and power transmission.

2. Stage Rigging: In the entertainment industry, multiple pulleys are crucial for stage rigging, enabling the safe and efficient movement of stage sets and equipment.

3. DIY Projects: Multiple pulleys are popular in DIY projects, allowing individuals to create mechanical advantage systems for lifting or moving objects at home or in workshops.

4. Automotive Repairs: Multiple pulleys are utilized in automotive repairs for tasks such as tensioning belts, controlling engine components, and operating mechanical systems.

5. Agriculture: In the agricultural sector, multiple pulleys are employed in machinery for tasks such as crop harvesting, irrigation systems, and grain handling.

Future Development and Opportunities

The future of multiple pulley products holds promising opportunities for further advancements. As industries continue to evolve, the demand for efficient and reliable load-handling solutions will increase. The development of innovative materials, such as composite pulleys, and the integration of advanced technologies, like smart sensors and automation, will shape the future of multiple pulley systems.

Choosing a Suitable Multiple Pulley

When selecting a multiple pulley, several factors should be considered:

1. Load Capacity: Determine the maximum load that the pulley will need to handle to ensure it can withstand the required weight.

2. Material: Choose a material based on the specific application requirements, considering factors such as strength, weight, and resistance to wear or corrosion.

3. Diameter and Size: Select the appropriate diameter and size of the pulley to ensure compatibility with the system and the desired mechanical advantage.

4. Type of Pulley: Consider the type of multiple pulley that best suits the application, whether fixed, movable, or a combination, based on the intended use and load handling requirements.

5. Bore Size: Ensure that the pulley’s bore size matches the shaft diameter to facilitate proper installation and alignment.

Conclusion

Multiple pulleys offer a range of performance characteristics that make them valuable in various industries. Their mechanical advantage, versatility, and smooth operation contribute to their widespread use in industrial machinery, stage rigging, DIY projects, automotive repairs, agriculture, and more. By selecting the right multiple pulley based on load capacity, material, diameter and size, type of pulley, and bore size, optimal performance and efficiency can be achieved. The future of multiple pulley systems holds great potential for further advancements and innovative applications, ensuring their continued relevance and significance in the ever-evolving world of machinery and load handling.

Author: Dream (Content sourced from the internet, only for reference purposes, our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are perfectly suited for original spare parts. For original spare parts, please contact the original factory or supplier.)