Product Description

Customize Plastic wheel Polyurethane PU Roller Bearing

We can do as your size , color ,drawing, or samples.any needs, just contact us any time

| Product name | Plastic ball bearing wheels |

| ltem number | S323Z |

| Weight | 17g |

| Material | Nylon,PU |

| Color | White |

| Outline | White |

| Use | Mechanical equipment such as drawers |

| Size | 6*34.5*11mm(Accept customization) |

| Rolling body | Steel ball |

| Stock | Enough |

1.Delimit

Plastic bearings can be generally divided into plastic rolling bearings and plastic sliding bearings; the friction generated

when plastic rolling bearings work is rolling friction, while the sliding of plastic sliding bearings occurs when sliding; the

frictional friction depends on the manufacturing precision; The amount of friction of the bearing depends mainly on the

material of the sliding surface of the bearing.

2.The main purpose:

Mechanical and electrical equipment, fitness equipment, food machinery, furniture and decorationmaterials 1. High rigidity and high hardness, high impact strength even at low temperatures;

2. Excellent elasticity and good creep resistance For fast quotation, please inform below detials;

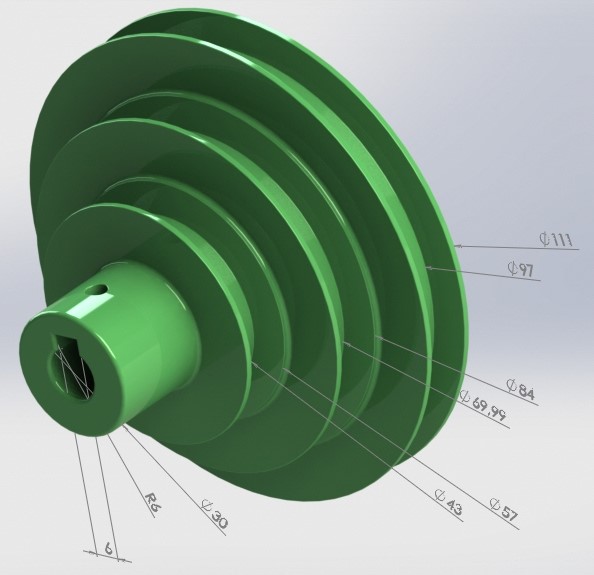

1. Product type

2. Size (provide samples or 2d/3d drawings for reference)

3. Material specification (or let us using environment)

4. Quantity request 5. Prefer color Companies strictly enforce the ISO9001(2008)international quality certification system,

the product quality conforms to the eu RoHS standard The company has professional product technical consultation and after-sales service;Good market

reputation (quality assurance, reasonable price, timely delivery!)We will wholeheartedly provide you with

the best quality products, the most thoughtful service! The company has rich experience, strong strength and participated in many high-end exhibitions;

Many partners from other countries are visiting

Cooperate with many CHINAMFG companie s

Q1. We don’t have drawings, can we produce according to the samples we provide?

A1. OK

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,

extruder, molding machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection

molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8. OK.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40ºC, and

the highest temperature is 300ºC. We can recommend materials according to the working conditions of your

company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, Rohs, product patent certificates, etc.

Q11. How scale is your company?

A11. Our company covers an area of 2,000 square CHINAMFG and has 100 employees /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Customized: | Customized |

|---|---|

| Color: | Multiple Colour |

| Type: | Rotating Wheel |

| Surface Treatment: | Chrome Plated |

| Size: | PA |

| Material: | Nylon |

| Customization: |

Available

| Customized Request |

|---|

Are there any regulations or guidelines for the installation of wall mount pulleys?

Yes, there are regulations and guidelines that govern the installation of wall mount pulleys to ensure safety and compliance with industry standards. Here’s a detailed explanation:

1. Building Codes:

Building codes provide regulations and guidelines for various aspects of construction, including the installation of pulleys. These codes may specify requirements for load capacities, structural integrity, and safety factors. It is important to consult the local building codes to ensure compliance with specific regulations in your area.

2. Occupational Safety and Health Administration (OSHA):

In the United States, the Occupational Safety and Health Administration (OSHA) sets guidelines for workplace safety. While OSHA does not have specific regulations for wall mount pulleys, they provide general guidelines for lifting and rigging operations. These guidelines address topics such as equipment inspection, safe working loads, and proper use of lifting devices.

3. Manufacturer’s Instructions:

Manufacturers of wall mount pulleys typically provide detailed installation instructions and guidelines specific to their products. These instructions outline recommended mounting methods, hardware requirements, and any special considerations for safe installation. It is important to carefully follow the manufacturer’s instructions to ensure proper installation and safe operation.

4. Professional Engineering Standards:

Professional engineering organizations, such as the American Society of Mechanical Engineers (ASME) or the European Committee for Standardization (CEN), develop standards and guidelines for various mechanical systems, including pulleys. These standards define best practices for design, installation, and operation, taking into account factors such as load capacities, safety factors, and material specifications.

5. Industry-Specific Regulations:

Depending on the specific industry or application, there may be additional regulations or guidelines for installing wall mount pulleys. For example, industries such as construction, manufacturing, or entertainment may have specific safety regulations or guidelines that apply to pulley installations in their respective contexts.

6. Professional Consultation:

When installing wall mount pulleys, it can be beneficial to consult with a professional engineer or a qualified contractor with expertise in rigging and lifting operations. These professionals can provide guidance on compliance with regulations, recommend appropriate hardware and installation methods, and ensure that the installation meets safety standards.

It is essential to familiarize yourself with the relevant regulations, guidelines, and manufacturer’s instructions when installing wall mount pulleys. By adhering to these standards, you can ensure the safe and compliant installation of the pulleys, reducing the risk of accidents and ensuring optimal performance.

How do wall mount pulleys contribute to space-saving and organization?

Wall mount pulleys are highly effective in contributing to space-saving and organization in various settings. Here’s a detailed explanation of how they achieve these benefits:

1. Vertical Storage:

By utilizing wall mount pulleys, items can be stored vertically, suspended from the ceiling or mounted on walls. This vertical storage approach maximizes the available space, especially in areas with limited floor space. It allows for efficient utilization of overhead and wall space, keeping the floor area clear and uncluttered.

2. Clearing Floor Space:

Wall mount pulleys help free up valuable floor space by lifting and suspending items off the ground. This is particularly useful in garages, workshops, or utility rooms where bulky items like bicycles, kayaks, or ladders can be stored overhead using pulley systems. Clearing the floor space improves mobility, reduces tripping hazards, and creates a cleaner and more organized environment.

3. Easy Access and Retrieval:

Using wall mount pulleys, items can be easily accessed and retrieved when needed. The pulley systems allow for smooth lifting, lowering, and retraction, making it convenient to reach stored items. This ease of access promotes efficient organization and saves time in locating and retrieving tools, equipment, or other stored objects.

4. Customizable Storage Solutions:

Wall mount pulleys offer flexibility in designing and customizing storage solutions. The height at which items are suspended can be adjusted by simply raising or lowering the pulleys. This adaptability allows for accommodating items of various sizes and shapes, optimizing the use of available space, and tailoring the storage system to specific needs.

5. Enhanced Organization:

By utilizing wall mount pulleys, items can be organized and categorized more effectively. Grouping similar items together and assigning specific pulleys or designated areas for different categories helps create a systematic and organized storage system. This not only enhances the overall appearance but also facilitates easy identification and retrieval of stored items.

6. Multi-Purpose Functionality:

Wall mount pulleys can serve multiple purposes, further contributing to space-saving and organization. A single pulley system can be used for storing different items by simply changing the attachments or hooks. This versatility allows for efficient use of the pulley systems and maximizes their organizational benefits.

Overall, wall mount pulleys provide practical solutions for space-saving and organization. They optimize storage capacity, create a clutter-free environment, and offer convenience in accessing and retrieving stored items. By incorporating wall mount pulleys into storage systems, both residential and commercial spaces can benefit from improved functionality and enhanced organization.

In which scenarios and industries are multiple pulley systems commonly employed?

Multiple pulley systems, also known as block and tackle systems, are commonly employed in various scenarios and industries where heavy lifting or load manipulation is required. Here are some scenarios and industries where multiple pulley systems are commonly used:

1. Construction:

Multiple pulley systems are extensively used in the construction industry for lifting heavy materials and equipment. They are employed in tasks such as hoisting construction materials to elevated heights, moving heavy machinery, and facilitating the installation of structural components.

2. Rigging and Sailing:

In the rigging and sailing industry, multiple pulley systems are utilized to control the positioning and tensioning of sails, ropes, and rigging on sailboats and larger vessels. These systems allow sailors to adjust the sail area and control the direction of the sail, enabling efficient propulsion and maneuverability.

3. Entertainment and Theater:

In the entertainment and theater industry, multiple pulley systems are employed for various purposes, such as lifting and moving stage props, scenery, and lighting equipment. These systems enable quick and precise changes in stage setups and facilitate dynamic performances.

4. Industrial Manufacturing:

In industrial manufacturing, multiple pulley systems are used for lifting and moving heavy machinery, components, and materials within factories and production facilities. They provide the necessary mechanical advantage to handle large loads safely and efficiently.

5. Mining and Extraction:

The mining and extraction industry relies on multiple pulley systems for various applications, including lifting and transporting heavy materials, lowering and retrieving mining equipment into underground mines, and facilitating the movement of minerals and ores across processing plants.

6. Material Handling and Logistics:

In material handling and logistics operations, multiple pulley systems are employed for tasks such as loading and unloading cargo, lifting and moving pallets, and operating conveyor systems. These systems enhance efficiency and productivity in warehouses, distribution centers, and shipping facilities.

7. Rescue and Emergency Services:

Multiple pulley systems play a crucial role in rescue and emergency services. They are used for tasks such as high-angle rescues, where individuals or equipment need to be lifted or lowered from elevated locations safely. These systems provide the necessary mechanical advantage to perform such operations with precision and control.

8. Agriculture and Farming:

In agriculture and farming, multiple pulley systems are utilized for various purposes, including lifting and moving heavy farm equipment, tensioning fences and cables, and facilitating the handling of large bales or hay. These systems assist farmers in performing tasks efficiently and reducing manual labor.

These are just a few examples, and multiple pulley systems find applications in various other industries and scenarios where heavy lifting, load manipulation, or precise control is required.

editor by CX

2024-04-03