Product Description

Product Description:

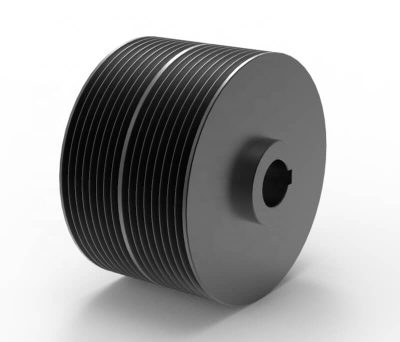

Ceramicproducts is applicable for wire or silk rolling of various winding machines and textile machinery. It is made of precise ceramic and polished up to Ra0.2, high hardness and smooth surface enable the enameled wire free from hurt during surface sliding.

The ceramic products is used to set less (friction is also less) location of pressure right. For cost reduction, according to using a request, smoothness polishing handicraft is allotted being (0.8 throw Ra) roughly, is throw (Ra accurate 0.4), surpasses essence throwing (Ra0.2). Be that single face is super-accurate at the same time as mark throw and two-sided super-accurate throw. Specification of China eye many, select and use specification listing in common use in support a customer the day after tomorrow now, also may demand making to order according to the customer.

The alumina ceramic products(zirconia ceramic products) is 1 of our feature products with a competitive price. Our company has many types of ceramic products, complete molds, and models, welcome to consult.

| Brand Name: | ZTF |

| Material: | 95%AL2O3, 99%AL2O3 or titanium oxide |

| Application: | Ceramic guide for wire |

| Polish: | Fine Polish degree Ra0.2 |

| Hardness: | ≥HRA85 |

| Volume Density: | ≥3.60 |

| Bending Strength: | ≥280 Mpa |

| Basic Tolerance: | +/-1% |

| Color: | Pink, White, Light Pink, Black, Dark Red |

| Molding Method: | LOW PRESSURE IN JECTION |

Well Polished Low Friction High Purity Alumina Textile Ceramic products.

The main features of textile ceramic eyelet

1. Low yarn tensions without any yarn damage

2. Long service life on both special yarns and raw materials with aggressive additives

3. Highest yarn cleanliness without any fault on silk occasion

3. Excellent mechanical strength, fracture toughness, and bending strength

4. Exceptional wear resistance and hardness better than metal ones

5. Good insulation, free of static electricity, resistant magnetic

6. Superb thermal conductivity coefficient and thermal shock property

7. Corrosion resistance in harsh working conditions

8. Excellent thermal shock resistance and good thermal stability

9. Nox-toxic, healthy material, eco-friendly material

10. Meet with RoHS, REACH regulation completely

The specification of textile Ceramic products:

Material option Alumina(Al2O3), Zirconia (ZrO2), Titania (TiO2)

Forming methods Dry pressed, Ceramic injection molding, Hot pressed

Specification OD can be from 1 to 50mm

Precision processing Precision Grinding, Polishing, Lapping,

Key parameters Fine grade roughness to be 0.4mm, diamond-like polish to be Ra0.1

Surface quality Free of cracks, foreign contamination, and mirror surface

Why Us:

- USD 1000 million sales every year;

- Excellent quality and Competitive price;

- Widely professional exporting experience all over the world;

- Well-trained and experienced staff will answer all your inquiries professional in any language;

- Good after-sales service offered.

- Culture

Culture:

We stick to the principle of the culture are Sustainability and Six High Standard: high-level management, high efficiency, high-qualified staffs, high-level skills, high-quality products, and high-speed developing sales. The best design includes consideration for the environment. That’s why we’re committed to making sure our processes, products, and people follow safe and environmentally-friendly practices. Other side, We prefer to bring the newest, most fashionable, high quality and healthiest products for our customer.

Service:

ZHENGTAIFENG METAL PRODUCT LIMITED products features complete presale, selling and after-sales service system, and provides detailed management and service for clients in terms of distribution channels. and provides professional and systematic advice for distributors.

Supplementary Service:

We have export license to assist our customers by handling export procedures. We have our team to control quality, arrange shipment, combine container (combine different kinds of items in 1 container from our factory to another). As we always care your thinking, we will be your professional partner to source your right products in China.

Suggestion:

Please kindly check the packages after you receive the goods, if you have any problem, please get in touch with us as soon as possible .

Contact us:

More products are available in ZHENGTAIFENG. They are all in competitive price and of good quality, just go to our company page to see the details.

If you find or not find the products you need, please have no hesitate to let us know.

FAQ:

| 1.Q:Are you a factory or trading company? |

| A:We are a professional manufacturer. Welcome to visit us, we’Il pick you up at GuangZhou airport or HangZhou airport. |

| 2.Q:Where is your factory located? |

| A:Our factory is located in HangZhou, ZheJiang Province, next to HangZhou. Warmly welcome domestic and foreign customers to visit! |

| 3.Q:How can I get a sample to test your quality? |

| A:Most samples are free except special products. New clients are expected to pay the courier. |

| 4.Q:How about your payment terms? |

| A:T/T in advence or one month after shipment |

| 5.Q:When can you deliver the goods? |

| A:If stock available, we can deliver it within 2 days. If not, that would be 5-7 working days after getting the deposit. |

| 6.Q:Does your company accept OEM or ODM production? |

| A:Yes, we are experienced in operating OEM & ODM, just send the detailed requirements. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Warranty: | One Year |

|---|---|

| Classification: | Threaded Parts |

| Processing Type: | Stamping Processing |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do advancements in materials and technology impact the design of modern wall mount pulleys?

Advancements in materials and technology have a significant impact on the design of modern wall mount pulleys, leading to improved performance, durability, and functionality. Here’s a detailed explanation:

1. Lightweight and High-Strength Materials:

Modern wall mount pulleys benefit from the use of lightweight yet high-strength materials such as aluminum alloys, stainless steel, or engineered plastics. These materials offer excellent strength-to-weight ratios, allowing for the design of pulleys that are both strong and lightweight. The use of lightweight materials reduces the overall weight of the pulley system, making it easier to install and operate.

2. Enhanced Durability:

New materials and manufacturing techniques contribute to enhanced durability in modern pulley designs. Materials with improved resistance to corrosion, wear, and fatigue are employed to ensure longevity, even in challenging environments. This durability extends the lifespan of the pulleys and reduces the need for frequent replacements.

3. Low-Friction Coatings and Bearings:

Advancements in technology have led to the development of low-friction coatings and high-quality bearings for pulley systems. These coatings and bearings minimize friction, resulting in smoother operation, reduced wear, and improved efficiency. Low-friction pulleys require less force to operate, making them more user-friendly and energy-efficient.

4. Design Optimization:

Materials and technology advancements allow for design optimization in modern wall mount pulleys. Computer-aided design (CAD) software and simulation tools enable engineers to analyze and optimize the pulley geometry, ensuring optimal load distribution and stress management. This results in pulleys that can handle higher loads, have reduced weight, and exhibit improved performance.

5. Innovative Features and Accessories:

Advancements in technology have facilitated the incorporation of innovative features and accessories into modern wall mount pulleys. For example, some pulleys now include built-in braking systems, locking mechanisms, or quick-release features for added safety and convenience. Additionally, pulley systems may integrate with smart home technology, allowing for remote control or automation of lifting operations.

6. Precision Manufacturing:

Advanced manufacturing processes, such as CNC machining and 3D printing, enable the production of complex and precise pulley components. These processes ensure consistent quality and accuracy in the manufacturing of modern pulleys, resulting in smoother operation, better alignment, and improved overall performance.

Overall, advancements in materials and technology have revolutionized the design of modern wall mount pulleys, leading to lighter, stronger, and more durable products. With improved friction reduction, optimized designs, innovative features, and precise manufacturing, modern pulleys offer enhanced performance and functionality for a wide range of lifting and rigging applications.

Are there specific safety considerations when using wall mount pulleys for lifting or rigging?

Yes, there are specific safety considerations that should be taken into account when using wall mount pulleys for lifting or rigging purposes. Here’s a detailed explanation:

1. Load Capacity:

It is crucial to ensure that the wall mount pulleys used for lifting or rigging are rated for the intended load capacity. Exceeding the load capacity can lead to pulley failure, causing accidents or damage. Always refer to the manufacturer’s specifications and guidelines to determine the appropriate load capacity of the pulleys.

2. Proper Installation:

Wall mount pulleys should be installed securely and according to the manufacturer’s instructions. The mounting surface should be strong and capable of supporting the weight and forces involved. It is important to use appropriate hardware and ensure proper anchoring to prevent pulley detachment or failure during lifting or rigging operations.

3. Inspections and Maintenance:

Regular inspections are essential to identify any signs of wear, damage, or deterioration in the pulleys or the mounting hardware. Inspect the pulleys, ropes, cables, or other lifting components for any fraying, corrosion, or deformation. Any damaged or worn-out parts should be replaced immediately. Additionally, perform routine maintenance, such as cleaning and lubrication, to ensure smooth operation and prevent premature failure.

4. Proper Rigging Techniques:

Using proper rigging techniques is critical for safe lifting operations. Ensure that the load is securely attached to the pulley system, and use appropriate slings, hooks, or connectors that are rated for the load. Follow industry best practices for rigging, including proper load balancing, avoiding sharp edges or abrasive surfaces, and maintaining a clear path for the load to prevent entanglement or interference.

5. Personal Protective Equipment (PPE):

When lifting or rigging with wall mount pulleys, it is important to use the appropriate personal protective equipment. This may include safety gloves, safety glasses, hard hats, or other protective gear depending on the specific lifting environment and associated hazards.

6. Training and Competence:

Only trained and competent individuals should operate wall mount pulleys for lifting or rigging purposes. Proper training ensures knowledge of safe practices, load limits, and proper use of equipment. Adequate supervision and adherence to established protocols help minimize the risk of accidents and ensure the safety of personnel involved.

By considering these safety considerations and implementing appropriate measures, the use of wall mount pulleys for lifting or rigging can be conducted safely and effectively, reducing the risk of accidents and promoting a safe working environment.

How do wall mount pulleys assist in various lifting and hoisting tasks?

Wall mount pulleys play a crucial role in assisting with various lifting and hoisting tasks. They provide mechanical advantage and enable the efficient transfer of force to lift or move heavy loads. Here’s a detailed explanation of how wall mount pulleys assist in these tasks:

1. Mechanical Advantage:

Wall mount pulleys are designed based on the principles of mechanical advantage. By utilizing multiple pulleys, they allow the user to exert less force to lift or move a heavy load. The mechanical advantage is achieved by distributing the load’s weight among multiple ropes or cables and redirecting the force applied.

2. Load Control:

Wall mount pulleys provide precise control over the lifting or hoisting process. By adjusting the position of the pulleys and the tension in the ropes, the user can control the speed, direction, and height of the load. This enables safe and accurate positioning of the load, even in challenging or confined spaces.

3. Increased Safety:

Using wall mount pulleys enhances safety in lifting and hoisting tasks. By reducing the amount of force required to lift heavy loads, they minimize the risk of strain or injury to the operator. Additionally, the mechanical advantage provided by pulleys allows for controlled and gradual lifting, reducing the chances of sudden load shifts or accidents.

4. Versatility:

Wall mount pulleys offer versatility in lifting and hoisting tasks. They can be mounted on walls, beams, or other suitable structures, providing flexibility in their application. The pulleys can be positioned and configured to accommodate different load sizes, weights, and angles, making them adaptable to various lifting requirements.

5. Efficiency and Productivity:

By reducing the physical effort required, wall mount pulleys improve efficiency and productivity in lifting and hoisting tasks. They enable individuals to handle heavier loads or perform tasks that would otherwise be challenging or time-consuming. This efficiency translates into increased productivity and reduced labor costs in various industries and applications.

6. Reducing Strain on Equipment:

Wall mount pulleys help distribute the load’s weight evenly, reducing strain on the lifting equipment. This can extend the lifespan of the equipment and minimize the risk of premature wear or failure. By utilizing pulleys, the load is evenly distributed, reducing the stress on individual components and ensuring smoother operation.

Overall, wall mount pulleys provide mechanical advantage, load control, safety, versatility, and efficiency in lifting and hoisting tasks. Their application spans across industries such as construction, manufacturing, logistics, and many others where heavy loads need to be moved or positioned with precision.

editor by CX

2024-04-10