Product Description

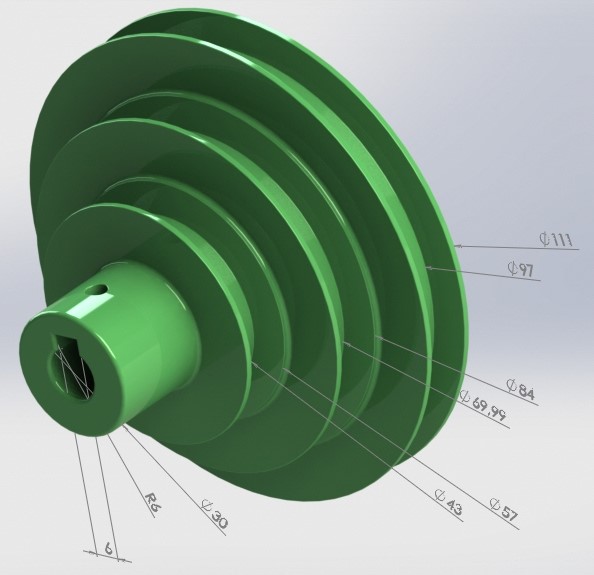

25 YEARS manufacturer Multiple engine/Size Crankshaft Tensioner, Belt Pulley Single 4BD1 4BG1 Replacement of Many Types of machine excavator.

Our main products:

steel cover lock, filter, oil grid, pump, cylinder head, crankshaft, camshaft, connecting rod, connecting rod bearing, valve, plunger, nozzle, exhaust valve, engine assembly, intake pump , fan blade, engine preheater, radiator, intake valve, main bearing, crankshaft bearing, nozzle, nozzle pipe, oil pump, piston, piston pin, piston ring, plunger, valve seat, thrust bearing, valve guide, valve Seats, valve seals, gasket sets, water pumps, turbochargers, generators, starters, sensors…

Please click here>>>>Contact us for more factory price,shipping and discounts

| ENGINE CUSHION | ||||||||||||||

| NO. | LB NO. | Model | OEM NO. | Name | NO. | LB NO. | Model | OEM NO. | Name | NO. | LB NO. | Model | OEM NO. | Name |

| 1 | KLB-Q3 | BELT TENSIONER | 15 | KLB-Q0017 | SK350-8 4pieces groove | BELT TENSIONER | 28 | KLB-Q0032 | 4BD1 4BG1 A:singlePK B:3PK |

3389198 | CRANKSHAFT PULLEY | |||

| 3 | KLB-Q0003 | 6CT | 3967190 | BELT TENSIONER | 16 | KLB-Q0018 | SK460 3pieces groove | BELT TENSIONER | 29 | KLB-Q0033 | EX200-1/3 6BD1 | CRANKSHAFT PULLEY | ||

| 4 | KLB-Q0004 | EC210 | 462280 | BELT TENSIONER | 17 | KLB-Q0019 | VOLVO360 | BELT TENSIONER | 30 | KLB-Q0034 | 6D31(NEW) | 173*140*34 | CRANKSHAFT PULLEY | |

| 5 | KLB-Q0005 | E325C | 144-1102 | BELT TENSIONER | 18 | KLB-Q571 | S6K | BELT TENSIONER | 31 | KLB-Q0035 | 6D31(OLD) | 160*120*34 | CRANKSHAFT PULLEY | |

| 6 | KLB-Q0006 | PC200-8 | BELT TENSIONER | 19 | KLB-Q0571 | PC60 4D95 | 150*66*43 | CRANKSHAFT PULLEY | 32 | KLB-Q0036 | E200B/320 | 160*113*45 | CRANKSHAFT PULLEY | |

| 7 | KLB-Q0007 | VOLVO210 stainless steel | BELT TENSIONER | 20 | KLB-Q0571 | PC120-6 | CRANKSHAFT PULLEY | 33 | KLB-Q0037 | E320B | 160*110*45 | CRANKSHAFT PULLEY | ||

| 8 | KLB-Q0008 | VOLVO360 | BELT TENSIONER | 21 | KLB-Q571 | PC200-3 6D105 | 144*113*39 6138-31-1480 | CRANKSHAFT PULLEY | 34 | KLB-Q0038 | E320C | 170*143*45 | CRANKSHAFT PULLEY | |

| 9 | KLB-Q0009 | CA016/C7 | BELT TENSIONER | 22 | KLB-Q0571 | PC200-5 6D95 | 150*110*41 6207-31-1410 | CRANKSHAFT PULLEY | 35 | KLB-Q0039 | DH220-5 DB58 | CRANKSHAFT PULLEY | ||

| 10 | KLB-Q571 | VOLVO480 with Belt groove | BELT TENSIONER | 23 | KLB-Q0571 | PC200-6 6D95 | 155*154*42 6209-31-1410 | CRANKSHAFT PULLEY | 36 | KLB-Q0014 | DH | 2107-6004B | BELT TENSIONER | |

| 11 | KLB-Q0011 | VOLVO480 | BELT TENSIONER | 24 | KLB-Q0026 | PC200-6 6D102 | 6735-61-3280 220*54*19 | CRANKSHAFT PULLEY | 37 | KLB-Q0015 | EX | BELT TENSIONER | ||

| 12 | KLB-Q0012 | VOLVO480 | BELT TENSIONER | 25 | KLB-Q0571 | PC300-3 PC400 6D125 | 182*118*43 | CRANKSHAFT PULLEY | 38 | KLB-Q571 | EX200-5 6BG1 3pieces groove | 230*120*40 | CRANKSHAFT PULLEY | |

| 13 | KLB-Q0013 | E320C | BELT TENSIONER | 26 | KLB-Q571 | A:PC300-6 6D108 doublePK | 144*127*40 | CRANKSHAFT PULLEY | 39 | KLB-Q0030 | 4D31 | 168*100*35 | CRANKSHAFT PULLEY | |

1Q:What is your brand?

1A:Our own brand: Mita Group and its range of excavator parts.

2Q:Do you have your own factory? Can we have a visit?

2A:Absolutely, you are alwayswelcome to visit our factory.

3Q:How do you control the quality of the products?

3A:Our factory was obtained the ISO9001CERTIFICATE.Every process of the production is strictly controlled. And all products will be inspected by QC before shipment.

4Q:How long is the delivery time?

4A:2 to 7 days for ex-stock orders. 15 to 30 days for production.

5Q:Can we print our company logo onproduct and package?

5A:Yes, but the quantity of the order is required. And we need you to offer the Trademark Authorization to us.

6Q:Can you provide OEM BRAND package?

6A:Sorry, we can only offer our company ACT BRAND package or neutral packing,blank package ifyou need, and the Buyers’ Brand as authorized.7Q:How long is the warranty period?7A:3 months /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO9001 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Material: | Aluminum |

| Type: | Crankshaft Tensioner |

| Lb No.: | Klb-Q0032 |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there any regulations or guidelines for the installation of wall mount pulleys?

Yes, there are regulations and guidelines that govern the installation of wall mount pulleys to ensure safety and compliance with industry standards. Here’s a detailed explanation:

1. Building Codes:

Building codes provide regulations and guidelines for various aspects of construction, including the installation of pulleys. These codes may specify requirements for load capacities, structural integrity, and safety factors. It is important to consult the local building codes to ensure compliance with specific regulations in your area.

2. Occupational Safety and Health Administration (OSHA):

In the United States, the Occupational Safety and Health Administration (OSHA) sets guidelines for workplace safety. While OSHA does not have specific regulations for wall mount pulleys, they provide general guidelines for lifting and rigging operations. These guidelines address topics such as equipment inspection, safe working loads, and proper use of lifting devices.

3. Manufacturer’s Instructions:

Manufacturers of wall mount pulleys typically provide detailed installation instructions and guidelines specific to their products. These instructions outline recommended mounting methods, hardware requirements, and any special considerations for safe installation. It is important to carefully follow the manufacturer’s instructions to ensure proper installation and safe operation.

4. Professional Engineering Standards:

Professional engineering organizations, such as the American Society of Mechanical Engineers (ASME) or the European Committee for Standardization (CEN), develop standards and guidelines for various mechanical systems, including pulleys. These standards define best practices for design, installation, and operation, taking into account factors such as load capacities, safety factors, and material specifications.

5. Industry-Specific Regulations:

Depending on the specific industry or application, there may be additional regulations or guidelines for installing wall mount pulleys. For example, industries such as construction, manufacturing, or entertainment may have specific safety regulations or guidelines that apply to pulley installations in their respective contexts.

6. Professional Consultation:

When installing wall mount pulleys, it can be beneficial to consult with a professional engineer or a qualified contractor with expertise in rigging and lifting operations. These professionals can provide guidance on compliance with regulations, recommend appropriate hardware and installation methods, and ensure that the installation meets safety standards.

It is essential to familiarize yourself with the relevant regulations, guidelines, and manufacturer’s instructions when installing wall mount pulleys. By adhering to these standards, you can ensure the safe and compliant installation of the pulleys, reducing the risk of accidents and ensuring optimal performance.

Are there different sizes and load capacities available for wall mount pulleys?

Yes, there are different sizes and load capacities available for wall mount pulleys. Manufacturers offer a variety of options to accommodate various lifting and hoisting requirements. Here’s a detailed explanation:

1. Sizes:

Wall mount pulleys come in different sizes to suit different applications. The size of a pulley is typically determined by its diameter, which can range from small pulleys for light-duty tasks to larger pulleys for heavy-duty applications. The size of the pulley affects factors such as the amount of rope/cable it can accommodate and the mechanical advantage it provides.

2. Load Capacities:

Wall mount pulleys are designed to handle specific load capacities. The load capacity refers to the maximum weight that the pulley system can safely lift or hoist. Pulleys are typically rated for different load capacities, ranging from a few hundred pounds to several tons or more. It’s crucial to select a pulley with a load capacity that matches or exceeds the weight of the intended load.

3. Ratings and Specifications:

Manufacturers provide ratings and specifications for wall mount pulleys, which include information about their size, load capacity, and other relevant details. These ratings help users determine the suitability of a pulley for a specific task and ensure safe and efficient operation.

4. Customization:

In some cases, manufacturers may offer customization options for wall mount pulleys. This allows customers to request pulleys with specific sizes or load capacities tailored to their unique requirements. Customization can be beneficial for specialized applications or when standard pulleys do not meet the desired specifications.

5. Safety Factors:

It’s important to consider safety factors when selecting wall mount pulleys. Manufacturers typically design pulleys with a safety factor in mind, which ensures that the pulley can handle loads beyond its rated capacity without compromising safety. The safety factor provides an additional margin of strength and reliability to account for unexpected variations in load or operating conditions.

When choosing wall mount pulleys, it’s essential to assess the specific lifting or hoisting needs and select pulleys that match the requirements in terms of size, load capacity, and safety factors. Consulting manufacturer guidelines and seeking expert advice can help ensure the correct selection and safe use of wall mount pulleys.

How do wall mount pulleys assist in various lifting and hoisting tasks?

Wall mount pulleys play a crucial role in assisting with various lifting and hoisting tasks. They provide mechanical advantage and enable the efficient transfer of force to lift or move heavy loads. Here’s a detailed explanation of how wall mount pulleys assist in these tasks:

1. Mechanical Advantage:

Wall mount pulleys are designed based on the principles of mechanical advantage. By utilizing multiple pulleys, they allow the user to exert less force to lift or move a heavy load. The mechanical advantage is achieved by distributing the load’s weight among multiple ropes or cables and redirecting the force applied.

2. Load Control:

Wall mount pulleys provide precise control over the lifting or hoisting process. By adjusting the position of the pulleys and the tension in the ropes, the user can control the speed, direction, and height of the load. This enables safe and accurate positioning of the load, even in challenging or confined spaces.

3. Increased Safety:

Using wall mount pulleys enhances safety in lifting and hoisting tasks. By reducing the amount of force required to lift heavy loads, they minimize the risk of strain or injury to the operator. Additionally, the mechanical advantage provided by pulleys allows for controlled and gradual lifting, reducing the chances of sudden load shifts or accidents.

4. Versatility:

Wall mount pulleys offer versatility in lifting and hoisting tasks. They can be mounted on walls, beams, or other suitable structures, providing flexibility in their application. The pulleys can be positioned and configured to accommodate different load sizes, weights, and angles, making them adaptable to various lifting requirements.

5. Efficiency and Productivity:

By reducing the physical effort required, wall mount pulleys improve efficiency and productivity in lifting and hoisting tasks. They enable individuals to handle heavier loads or perform tasks that would otherwise be challenging or time-consuming. This efficiency translates into increased productivity and reduced labor costs in various industries and applications.

6. Reducing Strain on Equipment:

Wall mount pulleys help distribute the load’s weight evenly, reducing strain on the lifting equipment. This can extend the lifespan of the equipment and minimize the risk of premature wear or failure. By utilizing pulleys, the load is evenly distributed, reducing the stress on individual components and ensuring smoother operation.

Overall, wall mount pulleys provide mechanical advantage, load control, safety, versatility, and efficiency in lifting and hoisting tasks. Their application spans across industries such as construction, manufacturing, logistics, and many others where heavy loads need to be moved or positioned with precision.

editor by CX

2024-04-08