Product Description

Product Description

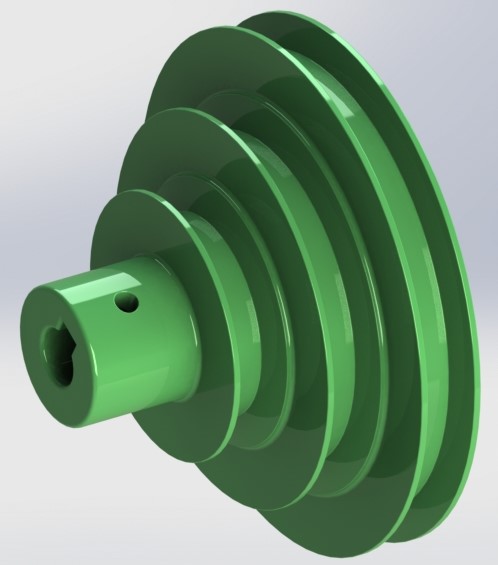

Product Name: Sliding Roller HN-U0828-9

Dimensions: ID=8mm; OD=28mm; Height=9mm

Outside Material: Polyformaldehyde (POM), Polyamide(PA6, PA66, Nylon), Polypropylene(PP), Polycarbonate(PC), Polyurethane(PU)

Insert Material: Carbon Steel, Chrome Steel, Stainless Steel

Color: All colors available

Profile Type:U Groove

Surface Treatment: Lathing

Structure: HN-625ZZ(ID=8mm, OD=28mm, Width=9mm)bearing injected with POM

Service: OEM&ODM

Experience: With 15 years manufacturing history

Adventage:

1) Built-in precise micro bearing;

2) Low noise, elegant performance and rolling smoothly;

3) Superior in quality and moderate in price;

4) We can supply both standard products and customized items according to the customers’ special requirements.

5) We can provide free samples for your reference.

| Item No. | Door and Window Plastic Bearing Pulley |

| Dimensions | OEM ODM |

| Material | Bearing -Chrome steel, carbon steel, stainless steel Plastic part- POM/ Nylon6 /Nylon66 +GF/PU/Rubber Housing part – Plastic(Nylon)/ Steel/ Zinc alloy die casting / Aluminium profile/ alu. Alloy die casting |

| Color | Original/black/white/Red/ Green/ Orange, or per customers’ requirement |

| Surface Treatment | Zinc plated/Nickle Plated/Black treatment/ Painting/Electrophoretic treatment |

| Features | heavy-duty,adjustable,low noise,easy installation,sliding smoothly,long life,standard,customized,etc. |

| Application | Sliding window and door, Sliding accessories, furniture accessories etc. |

| Packaing | Foil bag+Neutral Carton+Pallet, or per customers’ requirement |

| MOQ | 1000 pcs |

| Lead Time | According to the order q’ty |

| OEM& ODM | Technical drawing or sample is needed |

Payment & Packaging &Delivery:

Payment Terms:

1) 100% T/T

2) 30% T/T in advance, 70% against copy of BL

3) Paypal

Packaging Details: Standard export packing (Plastic bag, cartons and pallets or wooden case);

As customers’ requirement

Delivery Port: HangZhou / ZheJiang

Delivery Time: Normally ready goods and stock within 30 days or as the customer’s request

PS: 1) material and color can according to customers’ requirement.

2) we can make different size as per customers’ requirement.

Company Profile

FAQ

Q: Are you the manufacturer?

A: Yes, we are a professional manufacturer focused on door and window roller pulleys for over 15 years.

Q: Do you offer free samples?

A: Yes, we are very glad to offer free samples for you to check the quality.

Q: Can we make our own color box?

A: Yes, if the order quantity reaches 1000 sets, we can make a customized color box for you.

Q: Can we print our logo on the products?

A: Yes, we can print your logo on the products according to your design.

Q: How does your factory do regarding quality control?

A: 80% of the staff has 10 years experience, a mature skilled technical team, and a complete quality management system to ensure high quality.

Q: What is the after-sale service for the sliding rollers?

A: We have online technical support. If it is a quality problem, we will replace the broken ones with new ones.

Q: How long is the production time?

A: For samples in stock, shipped in 2 days. if not in stock, the lead time is in 7 days. For mass production, the lead time is around 15 days after receiving the deposit payment.

Q: How about the shipment?

A: For small orders, we can ship them by DHL, FedEx, UPS, TNT, etc. For mass production orders, we can ship them by sea or by air. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | / |

|---|---|

| Aligning: | Bearing |

| Separated: | Unseparated |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the quality and precision of wall mount pulley components impact performance?

The quality and precision of wall mount pulley components have a significant impact on the overall performance and functionality of the pulley system. Here’s a detailed explanation:

1. Smooth Operation:

High-quality pulley components, such as bearings and axles, ensure smooth and frictionless operation. Components manufactured with precision and made from durable materials reduce friction and minimize resistance, resulting in efficient and effortless movement of the pulley system.

2. Load Capacity:

The quality and precision of pulley components directly affect the load capacity of the system. Components designed and manufactured to high standards can withstand higher loads without failure. Reinforced materials, precise machining, and robust construction contribute to the overall strength and load-bearing capacity of the pulley system.

3. Durability and Longevity:

High-quality components enhance the durability and longevity of wall mount pulleys. Components made from durable materials, such as stainless steel or reinforced plastics, resist wear, corrosion, and fatigue. Precision manufacturing ensures that the components can withstand frequent or heavy use over an extended period without experiencing premature failure or degradation.

4. Alignment and Stability:

Precision in the manufacturing and assembly of pulley components ensures proper alignment and stability of the system. Accurate machining and tight tolerances result in components that fit together seamlessly, minimizing wobbling, misalignment, or unwanted movement. Proper alignment and stability are crucial for smooth operation and reliable performance of the pulley system.

5. Noise Reduction:

Precision-made pulley components reduce noise generated during operation. Components that fit together precisely and have minimal play or vibration produce less noise and operate quietly. This is particularly important in environments where noise reduction is desired, such as residential areas or indoor settings.

6. Safety:

The quality and precision of pulley components directly impact the safety of the system. Components that meet or exceed industry standards and undergo rigorous testing ensure reliable and safe operation. High-quality materials and precise manufacturing help prevent component failure, reducing the risk of accidents or injuries.

7. Efficiency:

Precision components contribute to the overall efficiency of wall mount pulley systems. Reduced friction, smooth operation, and optimal load distribution result in minimal energy loss and improved mechanical advantage. This translates to more efficient utilization of input force and improved performance of the pulley system.

Overall, the quality and precision of wall mount pulley components play a critical role in determining the performance, reliability, durability, and safety of the system. Investing in high-quality components ensures smoother operation, higher load capacity, increased longevity, and improved overall efficiency of the pulley system.

Are there different sizes and load capacities available for wall mount pulleys?

Yes, there are different sizes and load capacities available for wall mount pulleys. Manufacturers offer a variety of options to accommodate various lifting and hoisting requirements. Here’s a detailed explanation:

1. Sizes:

Wall mount pulleys come in different sizes to suit different applications. The size of a pulley is typically determined by its diameter, which can range from small pulleys for light-duty tasks to larger pulleys for heavy-duty applications. The size of the pulley affects factors such as the amount of rope/cable it can accommodate and the mechanical advantage it provides.

2. Load Capacities:

Wall mount pulleys are designed to handle specific load capacities. The load capacity refers to the maximum weight that the pulley system can safely lift or hoist. Pulleys are typically rated for different load capacities, ranging from a few hundred pounds to several tons or more. It’s crucial to select a pulley with a load capacity that matches or exceeds the weight of the intended load.

3. Ratings and Specifications:

Manufacturers provide ratings and specifications for wall mount pulleys, which include information about their size, load capacity, and other relevant details. These ratings help users determine the suitability of a pulley for a specific task and ensure safe and efficient operation.

4. Customization:

In some cases, manufacturers may offer customization options for wall mount pulleys. This allows customers to request pulleys with specific sizes or load capacities tailored to their unique requirements. Customization can be beneficial for specialized applications or when standard pulleys do not meet the desired specifications.

5. Safety Factors:

It’s important to consider safety factors when selecting wall mount pulleys. Manufacturers typically design pulleys with a safety factor in mind, which ensures that the pulley can handle loads beyond its rated capacity without compromising safety. The safety factor provides an additional margin of strength and reliability to account for unexpected variations in load or operating conditions.

When choosing wall mount pulleys, it’s essential to assess the specific lifting or hoisting needs and select pulleys that match the requirements in terms of size, load capacity, and safety factors. Consulting manufacturer guidelines and seeking expert advice can help ensure the correct selection and safe use of wall mount pulleys.

Can you explain the advantages of using a multiple pulley setup in lifting and tensioning applications?

Using a multiple pulley setup in lifting and tensioning applications offers several advantages. Here’s a detailed explanation of the advantages:

1. Mechanical Advantage:

A multiple pulley setup provides mechanical advantage, allowing for the lifting or tensioning of heavy loads with reduced effort. By distributing the load across multiple pulleys and ropes, the force required to lift or tension the load is divided, making it easier for the user to apply the necessary force.

2. Increased Lifting Capacity:

Due to the mechanical advantage it provides, a multiple pulley setup enables the lifting of heavier loads compared to a single pulley. By increasing the number of pulleys or sheaves in the setup, the load can be shared among the ropes, allowing for the lifting of loads that would be impractical or impossible with a single pulley.

3. Reduced Strain and Fatigue:

Using a multiple pulley setup reduces the strain and fatigue on the user. The mechanical advantage spreads the load across multiple ropes, which means the user needs to exert less force to achieve the desired lifting or tensioning result. This reduces the risk of strain or fatigue-related injuries, making the task safer and more manageable.

4. Precise Control:

A multiple pulley setup allows for precise control over the lifting or tensioning process. By adjusting the arrangement or configuration of the pulleys, the mechanical advantage can be fine-tuned to provide the desired level of control. This precision is particularly useful in applications where delicate or precise movements are required.

5. Versatility:

Multiple pulley setups offer versatility in lifting and tensioning applications. They can be configured in various ways to adapt to different load requirements and working conditions. By adjusting the number of pulleys, changing the arrangement, or using different types of pulleys, the setup can be customized to suit a wide range of applications.

6. Safety:

Using a multiple pulley setup enhances safety in lifting and tensioning tasks. The mechanical advantage reduces the risk of sudden load shifts or uncontrolled movements, providing better stability and control. Additionally, the reduced force required by the user decreases the likelihood of accidents or injuries due to overexertion.

7. Load Distribution:

A multiple pulley setup helps distribute the load evenly across the ropes. This balanced load distribution reduces the strain on individual ropes, minimizing the risk of premature wear or failure. It also ensures that the load is lifted or tensioned in a more stable and controlled manner.

8. Space Efficiency:

Multiple pulley setups can be more space-efficient compared to using larger single pulleys. By using smaller pulleys and spreading them out, the setup can accommodate tight spaces or provide flexibility in positioning. This can be advantageous in applications where space is limited or where maneuverability is required.

In summary, the advantages of using a multiple pulley setup in lifting and tensioning applications include mechanical advantage, increased lifting capacity, reduced strain and fatigue, precise control, versatility, enhanced safety, load distribution, and space efficiency. These benefits make multiple pulley setups a preferred choice in various industries and tasks that involve lifting or tensioning heavy loads.

editor by CX

2024-04-11