Product Description

Product Description

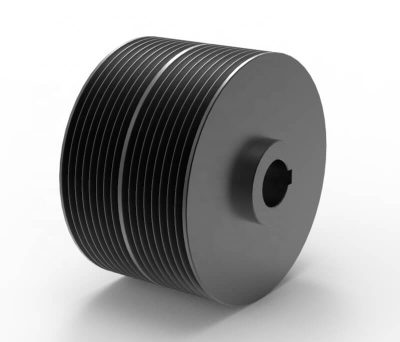

Product Name: Sliding Roller HN-R0522-6

Dimensions: ID=5mm; OD=22mm; Height=6mm

Outside Material: Polyformaldehyde (POM), Polyamide(PA6, PA66, Nylon), Polypropylene(PP), Polycarbonate(PC), Polyurethane(PU)

Insert Material: Carbon Steel, Chrome Steel, Stainless Steel

Color: All colors available

Profile Type:R Groove

Surface Treatment: Lathing

Structure: HN-625ZZ(ID=5mm, OD=22mm, Width=6mm)bearing injected with POM

Service: OEM&ODM

Experience: With 15 years manufacturing history

Adventage:

1) Built-in precise micro bearing;

2) Low noise, elegant performance and rolling smoothly;

3) Superior in quality and moderate in price;

4) We can supply both standard products and customized items according to the customers’ special requirements.

5) We can provide free samples for your reference.

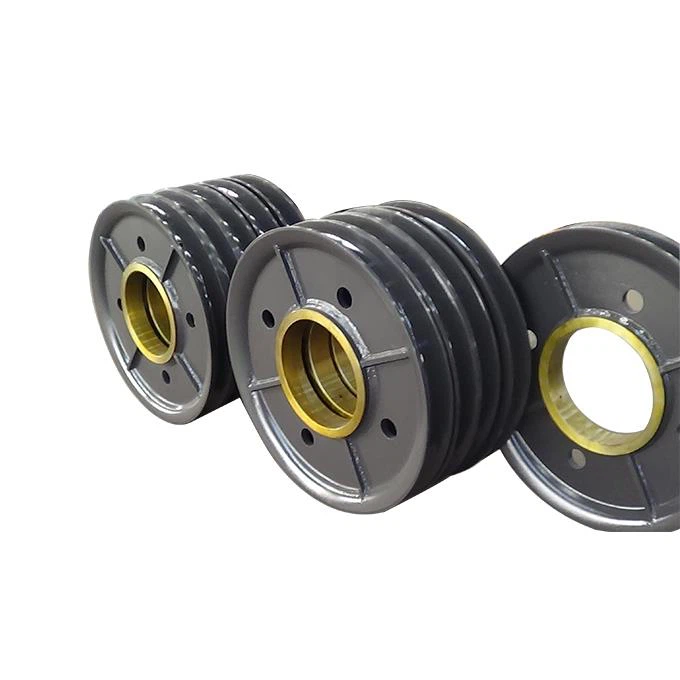

| Item No. | Door and Window Plastic Bearing Pulley |

| Dimensions | OEM ODM |

| Material | Bearing -Chrome steel, carbon steel, stainless steel Plastic part- POM/ Nylon6 /Nylon66 +GF/PU/Rubber Housing part – Plastic(Nylon)/ Steel/ Zinc alloy die casting / Aluminium profile/ alu. Alloy die casting |

| Color | Original/black/white/Red/ Green/ Orange, or per customers’ requirement |

| Surface Treatment | Zinc plated/Nickle Plated/Black treatment/ Painting/Electrophoretic treatment |

| Features | heavy-duty,adjustable,low noise,easy installation,sliding smoothly,long life,standard,customized,etc. |

| Application | Sliding window and door, Sliding accessories, furniture accessories etc. |

| Packaing | Foil bag+Neutral Carton+Pallet, or per customers’ requirement |

| MOQ | 1000 pcs |

| Lead Time | According to the order q’ty |

| OEM& ODM | Technical drawing or sample is needed |

Payment & Packaging &Delivery:

Payment Terms:

1) 100% T/T

2) 30% T/T in advance, 70% against copy of BL

3) Paypal

Packaging Details: Standard export packing (Plastic bag, cartons and pallets or wooden case);

As customers’ requirement

Delivery Port: HangZhou / ZheJiang

Delivery Time: Normally ready goods and stock within 30 days or as the customer’s request

PS: 1) material and color can according to customers’ requirement.

2) we can make different size as per customers’ requirement.

Company Profile

FAQ

Q: Are you the manufacturer?

A: Yes, we are a professional manufacturer focused on door and window roller pulleys for over 15 years.

Q: Do you offer free samples?

A: Yes, we are very glad to offer free samples for you to check the quality.

Q: Can we make our own color box?

A: Yes, if the order quantity reaches 1000 sets, we can make a customized color box for you.

Q: Can we print our logo on the products?

A: Yes, we can print your logo on the products according to your design.

Q: How does your factory do regarding quality control?

A: 80% of the staff has 10 years experience, a mature skilled technical team, and a complete quality management system to ensure high quality.

Q: What is the after-sale service for the sliding rollers?

A: We have online technical support. If it is a quality problem, we will replace the broken ones with new ones.

Q: How long is the production time?

A: For samples in stock, shipped in 2 days. if not in stock, the lead time is in 7 days. For mass production, the lead time is around 15 days after receiving the deposit payment.

Q: How about the shipment?

A: For small orders, we can ship them by DHL, FedEx, UPS, TNT, etc. For mass production orders, we can ship them by sea or by air.

| Contact Angle: | / |

|---|---|

| Aligning: | Bearing |

| Separated: | Unseparated |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do wall mount pulley systems contribute to improved efficiency and functionality in various settings?

Wall mount pulley systems offer several advantages that contribute to improved efficiency and functionality across various settings. Here’s a detailed explanation:

1. Mechanical Advantage:

Wall mount pulleys provide a mechanical advantage by distributing the force applied to the system. By redirecting the force through multiple pulleys, they reduce the amount of effort required to lift or move heavy objects. This increased mechanical advantage improves efficiency and allows for easier and more efficient operation.

2. Load Distribution:

Pulley systems distribute the load evenly across multiple pulleys and ropes or cables. This load distribution minimizes stress and strain on individual components, enhancing the system’s overall functionality and longevity. It also allows for the lifting or movement of heavier loads, expanding the capabilities of the system.

3. Versatility:

Wall mount pulley systems are highly versatile and can be adapted to various applications. They can be configured with different types and sizes of pulleys, ropes, or cables to meet specific needs. This versatility makes them suitable for a wide range of settings, including construction sites, manufacturing facilities, recreational areas, and residential spaces.

4. Space Optimization:

Wall mount pulleys utilize vertical space efficiently, making them ideal for environments with limited floor space. By mounting the pulleys on walls or overhead structures, they eliminate the need for bulky equipment or floor-mounted systems. This space-saving design allows for better organization and utilization of the available area.

5. Precise Positioning:

Wall mount pulleys enable precise positioning of objects or loads. By adjusting the position of the ropes or cables on the pulleys, users can control the vertical or horizontal movement with accuracy. This precision is particularly valuable in applications such as theatrical rigging, construction hoisting, or mechanical systems that require precise load manipulation.

6. Scalability:

Pulley systems are scalable, meaning they can be expanded or modified to accommodate changing needs. Additional pulleys, ropes, or cables can be added to the system to increase load capacity or change the mechanical advantage. This scalability provides flexibility and adaptability, allowing the system to grow or be adjusted as required in different settings.

7. Safety:

Wall mount pulley systems can enhance safety in various settings. By distributing the load and reducing the effort required for lifting or moving heavy objects, they minimize the risk of strain or injury to individuals operating the system. Additionally, the controlled movement provided by pulley systems allows for safer and more precise positioning of loads, reducing the risk of accidents or damage to the surroundings.

Overall, wall mount pulley systems improve efficiency and functionality in various settings by providing mechanical advantage, load distribution, versatility, space optimization, precise positioning, scalability, and enhanced safety. Their ability to optimize force distribution and enable controlled movement makes them valuable tools across industries and applications.

How does the placement and positioning of a wall mount pulley affect its function?

The placement and positioning of a wall mount pulley have a significant impact on its function and effectiveness in lifting and hoisting tasks. Here’s a detailed explanation of how the placement and positioning affect a wall mount pulley:

1. Stability and Structural Integrity:

The wall or surface on which the pulley is mounted should be stable and capable of supporting the weight and forces involved in the lifting or hoisting operation. The pulley should be securely attached to ensure its stability and prevent any movement during operation. Proper installation and positioning are crucial to maintaining the structural integrity of the pulley and ensuring safe and efficient operation.

2. Load Direction and Angle:

The placement and positioning of the wall mount pulley determine the direction and angle at which the load is lifted or moved. By adjusting the pulley’s position, the user can control the path and trajectory of the load. It’s important to consider factors such as clearance, obstacles, and the desired lifting path when positioning the pulley to ensure smooth and unobstructed movement of the load.

3. Mechanical Advantage:

The positioning of the wall mount pulley affects the mechanical advantage it provides. The mechanical advantage is determined by the number and arrangement of pulleys used in the system. By positioning the pulleys appropriately, the user can optimize the mechanical advantage and reduce the amount of force required to lift or move the load. Proper positioning can maximize the efficiency and effectiveness of the pulley system.

4. Rope/Cable Alignment:

The positioning of the wall mount pulley influences the alignment of the rope or cable used in the lifting or hoisting operation. The rope/cable should be properly aligned with the pulley’s grooves or sheaves to ensure smooth movement and minimize friction. Improper alignment can lead to increased wear on the rope/cable and reduce the efficiency of the pulley system.

5. Accessibility and Safety:

Proper placement and positioning of the wall mount pulley ensure easy accessibility and safe operation. The pulley should be positioned at a height and location that allows convenient access for attaching and detaching the load. Additionally, the placement should consider factors such as operator safety, clearance distances, and visibility to minimize the risk of accidents or injuries during the lifting or hoisting task.

Overall, the placement and positioning of a wall mount pulley directly impact its function and performance. By ensuring stable installation, adjusting the pulley’s position for optimal load direction and angle, optimizing the mechanical advantage, aligning the rope/cable correctly, and considering accessibility and safety, users can maximize the efficiency, safety, and effectiveness of the wall mount pulley in lifting and hoisting tasks.

In which scenarios and industries are multiple pulley systems commonly employed?

Multiple pulley systems, also known as block and tackle systems, are commonly employed in various scenarios and industries where heavy lifting or load manipulation is required. Here are some scenarios and industries where multiple pulley systems are commonly used:

1. Construction:

Multiple pulley systems are extensively used in the construction industry for lifting heavy materials and equipment. They are employed in tasks such as hoisting construction materials to elevated heights, moving heavy machinery, and facilitating the installation of structural components.

2. Rigging and Sailing:

In the rigging and sailing industry, multiple pulley systems are utilized to control the positioning and tensioning of sails, ropes, and rigging on sailboats and larger vessels. These systems allow sailors to adjust the sail area and control the direction of the sail, enabling efficient propulsion and maneuverability.

3. Entertainment and Theater:

In the entertainment and theater industry, multiple pulley systems are employed for various purposes, such as lifting and moving stage props, scenery, and lighting equipment. These systems enable quick and precise changes in stage setups and facilitate dynamic performances.

4. Industrial Manufacturing:

In industrial manufacturing, multiple pulley systems are used for lifting and moving heavy machinery, components, and materials within factories and production facilities. They provide the necessary mechanical advantage to handle large loads safely and efficiently.

5. Mining and Extraction:

The mining and extraction industry relies on multiple pulley systems for various applications, including lifting and transporting heavy materials, lowering and retrieving mining equipment into underground mines, and facilitating the movement of minerals and ores across processing plants.

6. Material Handling and Logistics:

In material handling and logistics operations, multiple pulley systems are employed for tasks such as loading and unloading cargo, lifting and moving pallets, and operating conveyor systems. These systems enhance efficiency and productivity in warehouses, distribution centers, and shipping facilities.

7. Rescue and Emergency Services:

Multiple pulley systems play a crucial role in rescue and emergency services. They are used for tasks such as high-angle rescues, where individuals or equipment need to be lifted or lowered from elevated locations safely. These systems provide the necessary mechanical advantage to perform such operations with precision and control.

8. Agriculture and Farming:

In agriculture and farming, multiple pulley systems are utilized for various purposes, including lifting and moving heavy farm equipment, tensioning fences and cables, and facilitating the handling of large bales or hay. These systems assist farmers in performing tasks efficiently and reducing manual labor.

These are just a few examples, and multiple pulley systems find applications in various other industries and scenarios where heavy lifting, load manipulation, or precise control is required.

editor by CX

2023-11-14